Technology

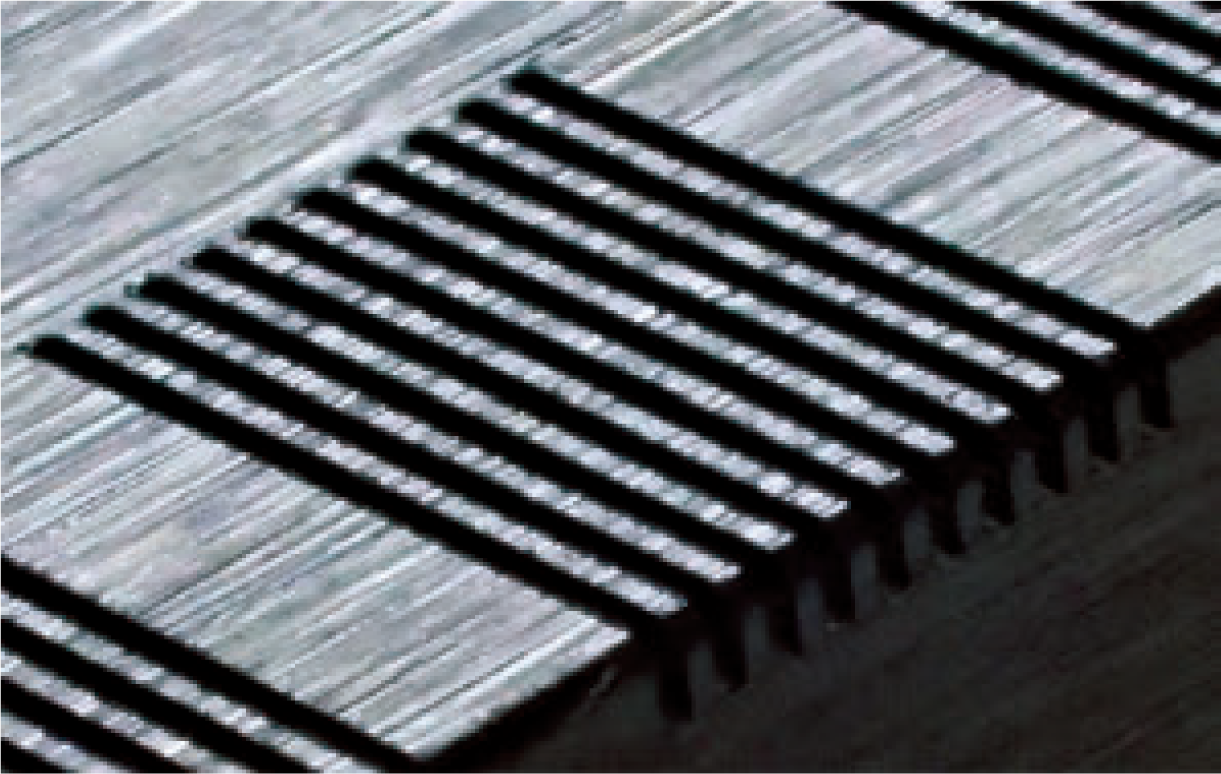

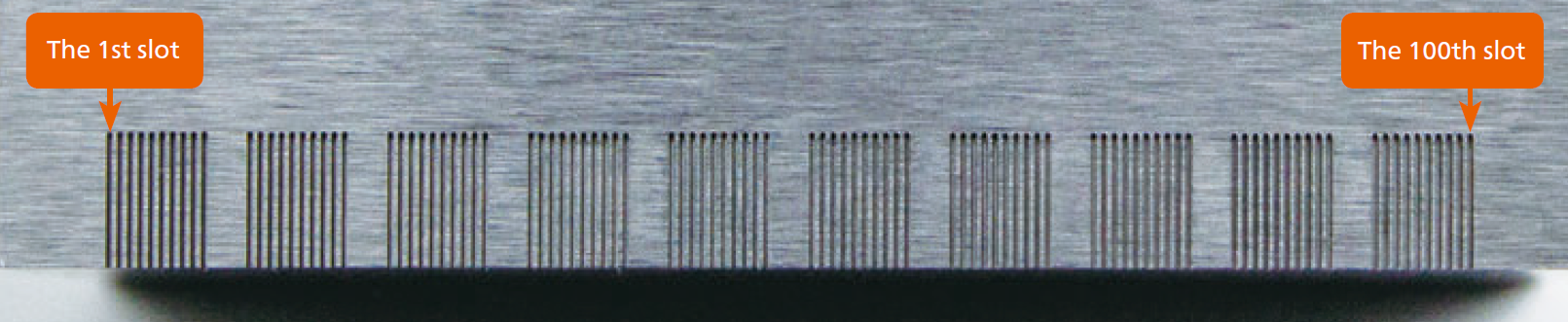

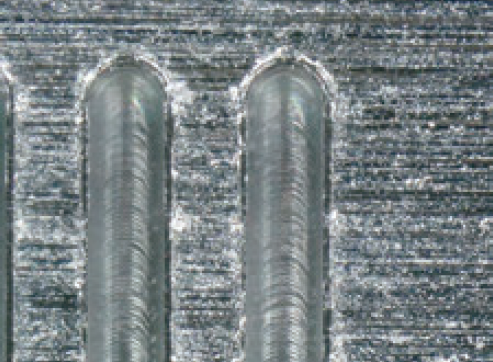

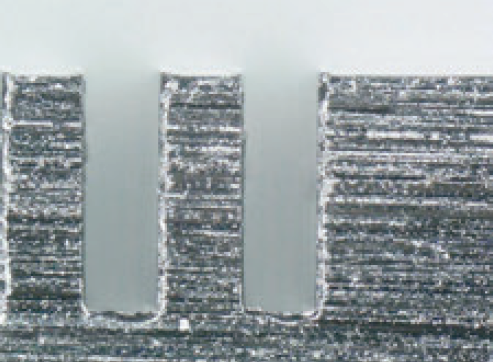

SHPR400 Cutting example of micro slotting

Work size : 30×10mm (Cutting depth: 0.3mm)

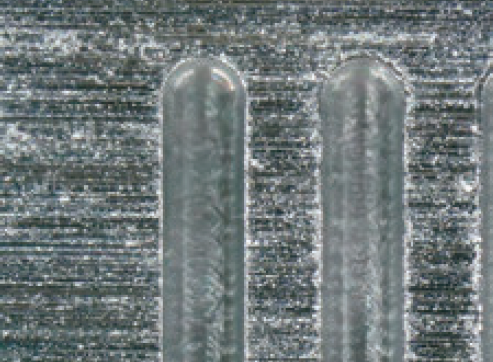

Profile : Width 0.1mm / Length 2.5mm / Depth 0.3mm

Material : DC53 60HRC

Coolant : Oil mist

Total machining time : 3hr 53min

Use only 1 end mill to finish 100 slots.

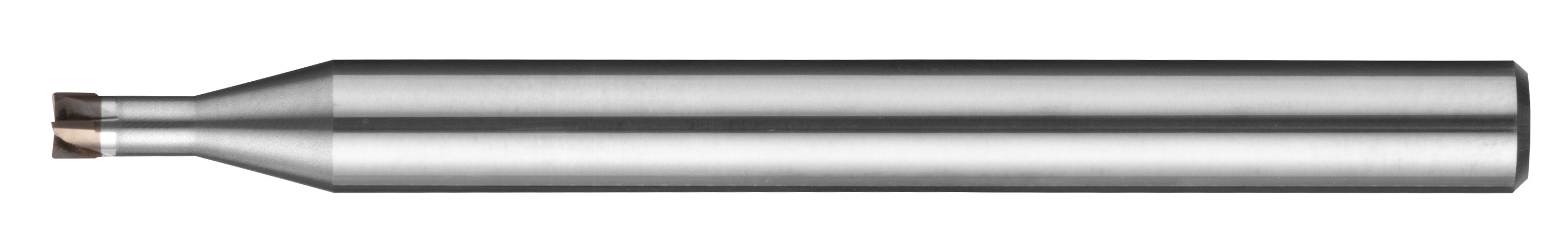

Tool

SHPR400

●New tool design has been developed to reduce the cutting resistance and upgrade the finishing accuracy!

●Realized 4-Flute type from φ0.1! Achieved higher efficient machining and more stable tool life in micro machining!

●The shank diameter accuracy is 2μm (-0.001~ -0.003), and also supports high precision shrink fit holders.

Cutting Condtions

Profile :

Width 0.1mm / Length 2.5mm / Depth 0.3mm

| Cutting process | Slotting |

| Spindle speed (min-1) |

120,000 |

| Feed (mm/min) |

300 |

| Depth of cut ap(mm) |

0.002 |

Result

| The 1st slot | The 100th slot | |

| Slot width Target 0.1mm |

|

|

| Actual | 0.101mm | 0.098mm |

| Slot depth Target 0.3mm |

|

|

| Actual | 0.299mm | 0.297mm |

Mesuring instrument : Nikon microscope MM40/Magnification rate : 100