Technology

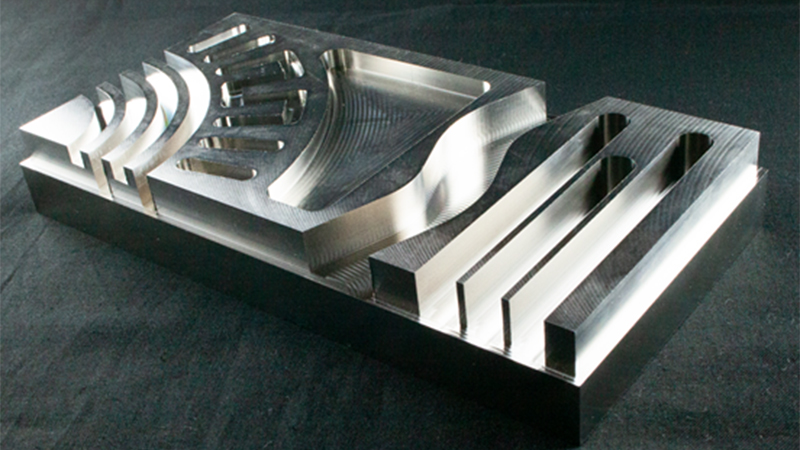

MSUSZ440 High Efficient Machining Example for Stainless Steels (SUS304)

Work size : 200×100mm

(Cutting depth : 12mm)

Material : SUS304

Total cutting time : 12min 26sec

Total 12.5 minutes for high efficient machining!

Only use 1 tool to complete all machining processes.

Tool

MSUSZ440

●Unequal flute spacing, unequal helix angle and high rigid end profile design to minimize chatter realize high efficient machining.

●New developed special edge profile realized multi-functional performance of side milling, slot milling and drilling approaches on stainless steel.

Milling Conditions

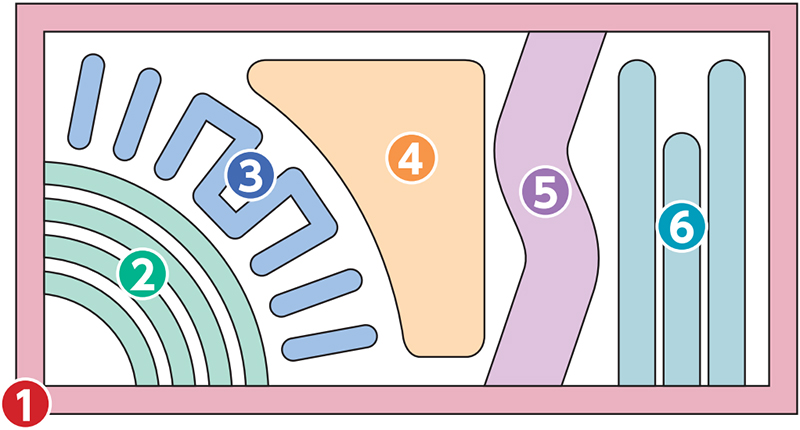

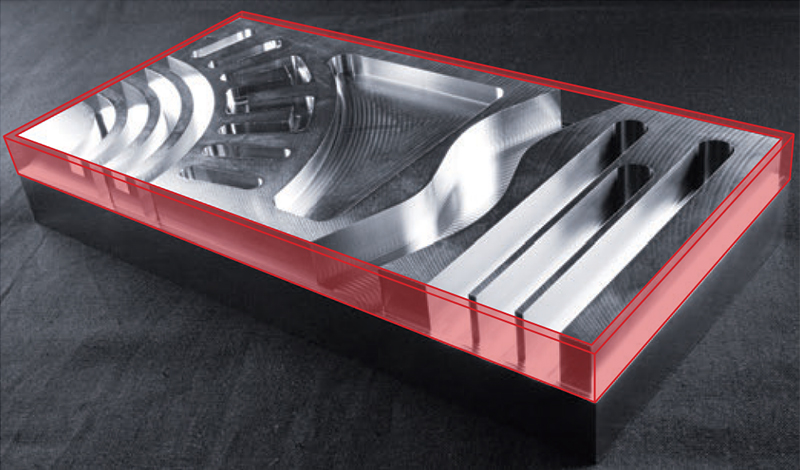

①The outer periphery part

※The outer periphery machining (Red part).

| Cutting process | Side | |

| Roughing | Finishing | |

| Spindle speed (min-1) |

5,000 | |

| Feed (mm/min) |

1,200 | |

| Depth of cut ap×ae(mm) |

12×1.2 | 12×0.05 |

| Stock (mm) |

0.05 | - |

| Cutting time | 1min 31sec | |

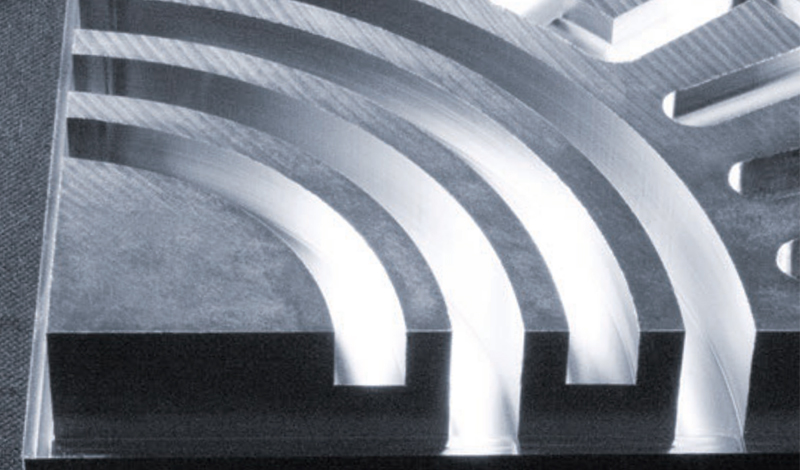

②Arc slot part

| Cutting process | Slot | |

| Depth of slot 6mm | Depth of slot 12mm | |

| Spindle speed (min-1) |

4,200 | |

| Feed (mm/min) |

400 | |

| Depth of cut ap(mm) |

6 | 6(2 times machining) |

| Cutting time | 1min 14sec | |

③Blind slot & Crank groove

| Cutting process | Slot | |||

| Depth of slot 3mm | Depth of slot 6mm | |||

| Drilling | Slot | Drilling | Slot | |

| Spindle speed (min-1) |

4,200 | |||

| Feed (mm/min) |

50 | 400 | 50 | 400 |

| Depth of cut ap(mm) |

3 | 3(2 times machining) | ||

| Cutting time | 54sec | |||

④Pocket

| Cutting process | Roughing | Finishing | ||

| Helical milling | Side | Bottom | Side | |

| Spindle speed (min-1) |

4,200 | 5,000 | ||

| Feed (mm/min) |

1,000 | 1,200 | ||

| Depth of cut ap×ae(mm) |

Approach angle 3° | 6×1.2 | 0.05×1 | 6×0.05 |

| Stock (mm) |

0.05 | - | ||

| Cutting time | 3min 51sec | |||

⑤Curved slot part (Trochoid milling)

| Cutting process | Roughing |

| Trochoid milling | |

| Spindle speed (min-1) |

5,000 |

| Feed (mm/min) |

1,200 |

| Depth of cut ap×ae(mm) |

12×1.2 |

| Cutting time | 2min 28sec |

⑥Thin wall part

| Cutting process | Roughing | Semi-finishing | Finishing |

| Slot | Side | ||

| Spindle speed (min-1) |

4,200 | 5,000 | |

| Feed (mm/min) |

400 | 1,200 | |

| Depth of cut ap×ae(mm) |

ap 6(2 times machining) | 12×1 | 12×0.05 |

| Cutting time | 2min 28sec | ||