Technology

Connect Model Cemented Carbide PCDSE / PCD End Mill

Work size: 10×10(mm)(Cutting Depth: 0.5mm)

Material: Cemented Carbide (92.5HRA)

Cutting time: 21hr 59min

Even if it was a long time Cemented Carbide machining, NS TOOL’s PCD end mill still can achieve high quality finished surface.

Tool

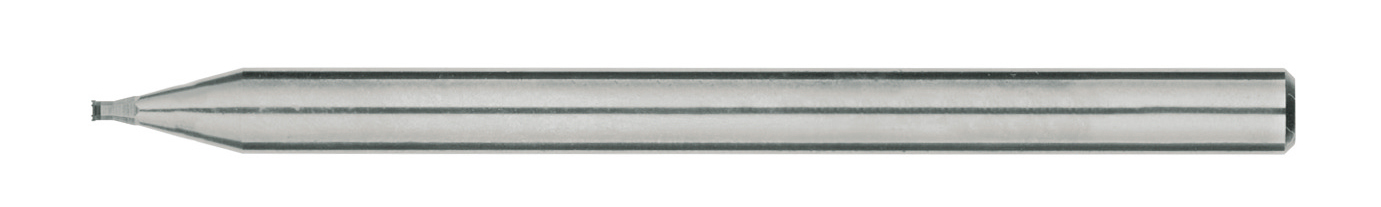

PCDSE

• Fine and stable milling surface realized on cemented carbide material.

• Possible to get the nano-level surface roughness required on ultra-high precision machining.

• NS original flute design of cutting edge enabled a strong resistance against wear and chipping.

DCMS

• Machinable on hard brittle materials such as cemented carbide material and ceramic.

• High adhered diamond coating was selected to achieve long hour milling.

Cutting Conditions

| Cutting process | Roughing | Contour finishing | Bottom finishing |

| Tool | DCMS Φ0.3 | PCDSE Φ0.5 | |

| Spindle speed (min-1) |

120,000 | 120,000 | 120,000 |

| Feed (mm/min) |

150 | 100 | 50 |

| Depth of cut ap×ae(mm) |

0.0015×0.1 | 0.002×0.001 | 0.0005×0.002 |

| Cutting length (m) |

98 | 64 | |

| Coolant | Water-insoluble fluid | ||

| Cutting time | 10hr 57min | 11hr 2min | |

Comment

Difference in dimension was ±0.002mm

The surface roughness of side walls and flat surface were Ra17.0nm/Rz96nm and Ra0.7nm/Rz8nm.

In order to reduce the spindle load, using the tool of 0.3 when roughing.