Technology

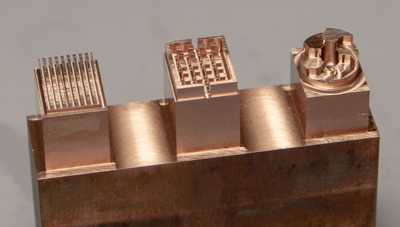

DHR237 Copper Tungsten multi profile electrode

Material : Copper Tungsten (W70%-Cu30%)

Processing size: 6.5×8(mm) Cutting depth1.5mm (Micro slit shape)

6.5×8(mm) Cutting depth1.5mm (Fine prism profile)

6.5×8(mm) Cutting depth 3mm (Cylindrical stage profile)

Tool

DHR237

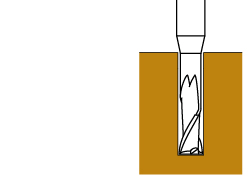

●Long neck end mill specialized for machining copper alloy.

●Helix angle 【37.5°】 degrees to achieve both sharpness and finished surface quality that prevents scratches on cutting surface.

●High quality and stable milling performance with long tool life by optimized design and DLC coating.

●Machining copper tungsten electrodes is also effective.

Cutting Conditions & Measuring result

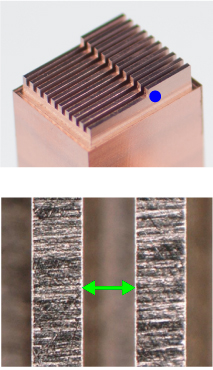

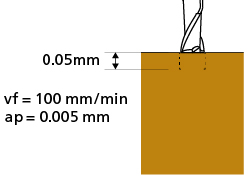

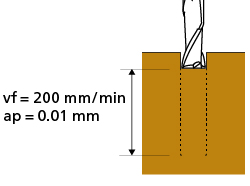

Micro slit shape

【Cutting condition】

| Process | Roughing(Slotting) | Finishing(Side milling) |

| Tool | DHR237 Φ0.3×1 | DHR237 Φ0.3×2 |

| Spindle speed (min-1) |

25,000 | |

| Feed (mm/min) |

200 100※ |

150 |

| Depth of cut ap×ae(mm) |

ap 0.01 ap 0.005※ |

0.1×0.005 |

| Stock (mm) |

0.005 | - |

| Coolant | Water-insoluble fluid | |

| Cutting time | 42min | 12min |

※Guide part machining from the upper surface to -0.05mm.

Result

Side

| Surface roughness | Ra0.101µm |

Slot width

| Target | 0.310mm |

| Actual | 0.307mm |

| Deflection | Within 0.001mm |

【Points of machining】

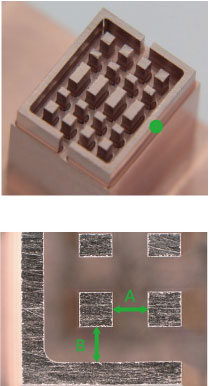

Fine prism profile

【Cutting condition】

| Process | Roughing | Finishing | ||

| Slotting | Side milling | |||

| Tool | DHR237 Φ0.5×1.5 | |||

| Spingle speed (min-1) |

26,000 | |||

| Feed (mm/min) |

500 | 550 | ||

| Depth of cut ap×ae(mm) |

ap0.07 | 0.3×0.02 | 0.3×0.005 | |

| Stock (mm) |

0.05 | 0.005 | - | |

| Coolant | Water-insoluble fluid | |||

| Cutting time | 13min | |||

【Measuring result】

Side

| Surface roughness | Ra 0.197 µm |

| A | B | |

| Target | 0.600mm | 0.600mm |

| Actual | 0.601mm | 0.599mm |

| Deflection | Within 0.001mm |

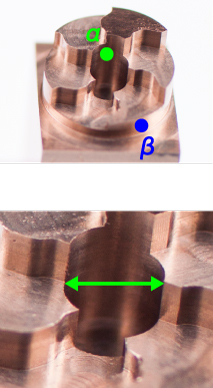

Cylindrical stage profile

【Cutting condition】

| Process | Roughing | Finishing | |

| Φ1.8 Helical milling | Side milling | ||

| Tool | DHR237 Φ0.8×3 | ||

| Spindle speed (min-1) |

12,000 | ||

| Feed (mm/min) |

500 | ||

| Depth of cut ap×ae(mm) |

ap0.07 (Helical R=0.25) |

0.5×0.02 | 0.5×0.005 |

| Stock (mm) |

0.25 | 0.005 | - |

| Coolant | Water-insoluble fluid | ||

| Cutting time | 33min | ||

【Measuring result】

Surface roughness

| α | β |

| Ra 0.182 µm | Ra 0.176 µm |

Center hole diameter

| Target | 1.800mm |

| Actual | 1.797mm |