Technology

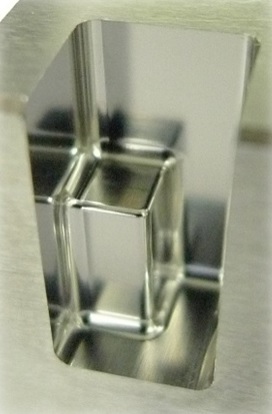

Deep Milling Model

STAVAX 52HRC

MRBTNH230 / Long Taper Neck Ball End Mill

Work size : 7.5 x 7 x 12 mm

Material : STAVAX 52HRC

Cutting Time : 2hr26min

More rigidity by adopting new designed taper neck! Realized high precision deep milling to the hardened steels.

Tool

MRBTNH230

•Taper neck type ball end mill improves accuracy for deep milling.

•Optimized taper neck design and MUGEN-COATING PREMIUM realized to show its higher ability for hardened steels.

•Lineup of total 159 sizes with high versatility 2-flute end mills.

Cutting Condition

| Cutting process | Roughing | Stock removal | Semi-finishing | Finishing |

| Tool | MRBTNH230 R1×1°30'×12 |

MRBTNH230 R0.5×1°30'×12 |

MRBTNH230 R0.5×1°30'×12 |

|

| Spindle speed (min-1) |

18,000 | 15,000 | 12,000 | 12,000 |

| Feed (mm/min) |

2,000 | 600 | 500 | 300 |

| Depth of cut ap×ae(mm) |

0.15×0.35 | 0.025×0.08 | 0.02×0.02 | 0.01×0.01 |

| Coolant | Oil mist | |||

| Cutting time | 14min | 12min | 23min | 1hr37min |

Comment

Accurate cutting has realized in tolerance -0.004mm. Also realized the surface roughness of Ra 0.121 μm and Rz 0.898 μm without chattering.