Products

PCD・Diamond End Mill

Cutting processing of highly fragile materials, such as a hard metal alloy…PCD end mill/diamond coating series that changed an impossibility to a possibility.

PCD End Mill

PCD (polycrystalline diamond) is adopted as a tool material. Many technical elements, such as a special cutting edge, provide the finishing quality and know-how for processing of the new generation and were developed to realize a nano-level finished surface by cutting work.

Square End Mill

PCDSE

Ball End Mill

PCDRB

Radius End Mill

PCDRS

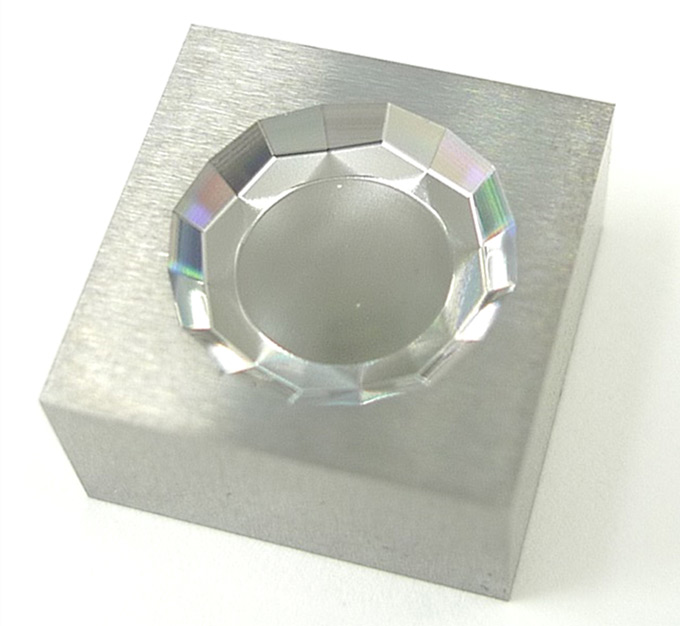

Mirror Finishing Sample

| Material | STAVAX 52HRC |

|---|---|

| Process | Finishing |

| Tool | PCDRB R1×5 |

| Spindle Speed [min-1] | 45,000 |

| Feed [mm/min] | 1,200 |

| Depth of cut (ap x ae)[mm] |

0.005×0.005 |

| Stock [mm] | 0.005 |

| Coolant | Water-insoluble fluid |

| Cutting time | 63ht 45min |

Work size:200×100mm

Reflection of cutting surface

Surface roughness(Ra):0.03∼0.05μm

Total cutting time: 64hrs.

Only using 1 piece PCDRB for finishing to realize mirror surface and the measurement of surface roughness is under Ra0.05μm.

Cemented carbide cutting sample

| Material | Cemented carbide 92.5HRA | |

|---|---|---|

| Process | Finishing | |

| Contour line | Scanning line | |

| Tool | PCDRS ⌀0.3×R0.05×0.3 | |

| Spindle Speed [min-1] | 40,000 | |

| Feed [mm/min] | 70 | |

| Depth of cut [mm] | ap 0.002∼0.006 | ae 0.005∼0.01 |

| Stock [mm] | 0.002 | 0.001 |

| Coolant | Water-insoluble fluid | |

| Cutting time | 6hr 23min | 3hr 25min |

Work size:15×15mm

Convex shape

Diameter at bottom shape 2.000mm/Height 0.924mm

【Tolerance】

| Flat Surface roughness(Ra) | 0.0027μm |

|---|---|

| Shape(maximum) | Diameter at bottom shape 0.003mm Height 0.002mm |

Nano-level surface roughness can be realized, even when milling cemented carbide

Finishing processing of cemented carbide alloy using PCDRB R0.5

| Work material | Cemented carbide 92.5 HRA |

|---|---|

| Spindle speed [min-1] | 60,000 |

| Feed [mm/min] | 1500 |

| Depth of cut

(ap x ae)[mm] |

0.0015 x 0.001 |

| Stock allowance [mm] | 0.001 |

| Coolant | Water-insoluble cutting oil |

| Time | 5hr40min |

Surface roughness(Ra):0.012∼0.030 μm

DIAMOND COATING End Mill

A cemented carbide end mill where the cutting edge surface is coated with diamond crystals. The end mill where the cutting edge can easily be designed and the shape most suitable for machining a hard and fragile material was developed. In addition, various types of technical developments for avoiding the peeling of the diamond coating that protects tools realized commercial products.

Square End Mill

DCMS

Ball End Millミル

DCMB

Finishing processing of cemented carbide alloy using DCMB R0.3

| Work material | Cemented carbide 92.5 HRA |

|---|---|

| Spindle speed [min-1] | 30,000 |

| Feed [mm/min] | 200 |

| Depth of cut

(ap x ae)[mm] |

0.002 x 0.005 |

| Stock allowance [mm] | 0.003 |

| Coolant | Water-insoluble cutting oil |

| Time | 2hr20min |

Surface roughness(Ra):0.05∼0.15 μm