Product

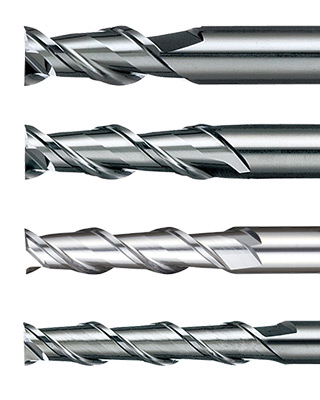

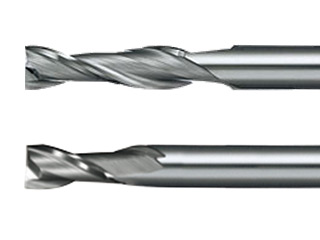

End Mills for aluminum and resin

AL series specialized for machining Aluminum alloy and Resin.

Shapes of tool designed for each work material differentiate machining quality and accuracy.

End mill for machining aluminum material

Rake angle for improving cutting quality and enlarged chip pocket realized high efficiency machining. Furthermore, the special treatment of a cutting edge restricting chattering during machining contributes to the improvement of machined surface quality and the extension of the service life.

Lineup of tools where the cutter lengths are two to five times the cutter diameter

Capable plunging and deep milling

3-flute medium end mill adoptable for slotting, side milling and plunging

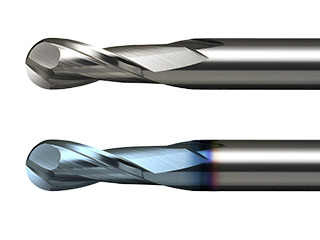

Expansion of DLC coating application

Lineup of even ball end mills

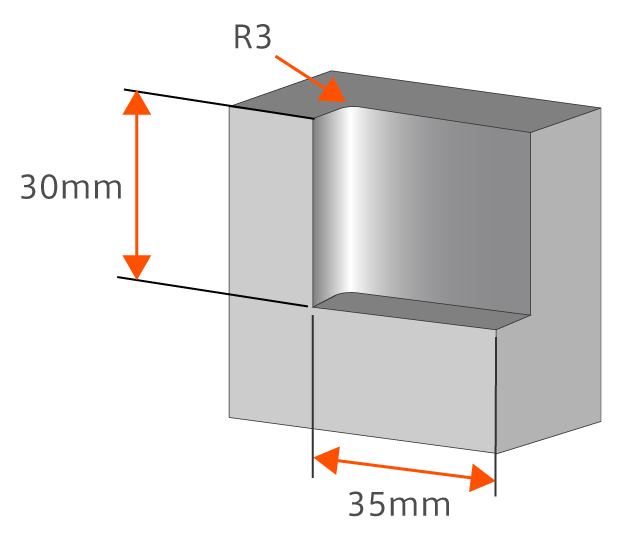

Excellent chatter prevention① Comparison of crossover corner

| Material | A5052 | |

|---|---|---|

| Tool | AL5D-2 φ6 | |

| Spindle Speed [min-1] | 12,000 | |

| Feed [mm/min] | 800 | |

| Cutting Time

(ap x ae)[mm] |

Roughing | 30 x 0.6 |

| Finishing | 30 x 0.06 | |

| Coolant | Water soluble oil | |

Work Size:35 x 50 x 50 mm

By adopting special edge profile, AL series prevent chattering more excellently on the high speed cutting condition than other brand.

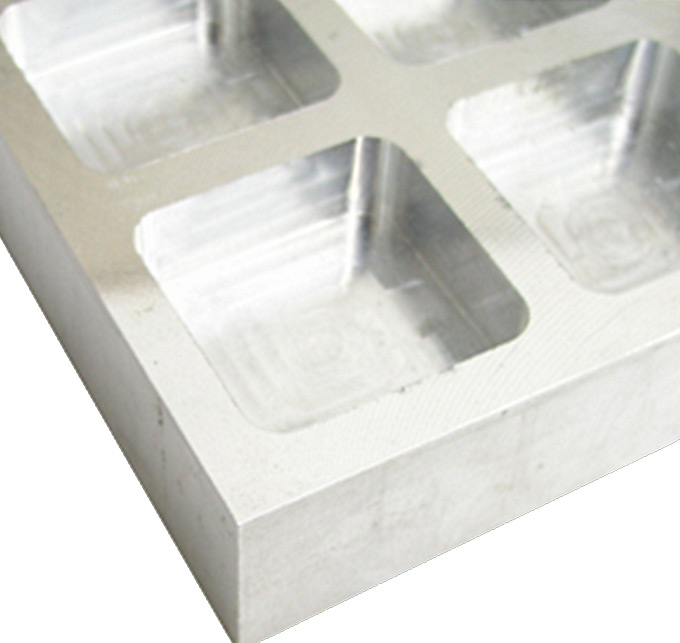

Excellent chatter prevention② Comparison of cutting speed

Large chip pocket,sharpness shearing ability and special edge profile stabilize milling performance with high speed cutting condition.

High speed cutting (ALZ345 Φ6)

| Work material | A5052 | |

|---|---|---|

| Spindle speed [min-1] | 10,000 | |

| Feed [mm/min] | Side milling | 3,500 |

| Plunging milling | 800 | |

| Depth of cutting

(ap x ae)[mm] |

Roughing | 9 x 3 |

| Finishing | 3 x 0.1 | |

| Coolant | Water soluble Oil | |

| Cutting time (1 pocket) |

45 sec | |

Pocket size:44 x 44 x 18 mm

End mill for machining resin material

Cutting-edge design specialized for processing a resin material realized high quality machining with minimized burrs. Size variations, such as an extremely long cutter and long neck and a short cutter with high rigidity are rich in order to respond to various processing shapes.

Square end mill

RSE230・RSES230

Ball end mill

RSB230

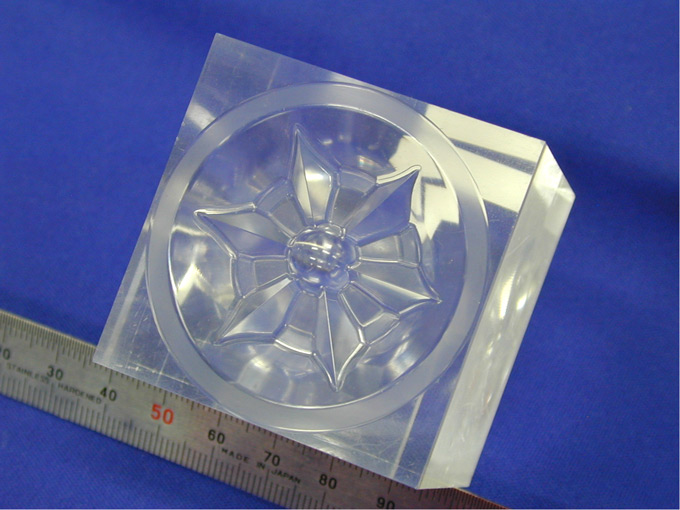

Finishing (RSB230 R1 x 6)

| Work material | Acrylic |

|---|---|

| Spindle speed [min-1] | 20,000 |

| Feed [mm/min] | 1,600 |

| Depth of cut

(ap x ae)[mm] |

0.02 x 0.03 |

| Coolant | Oil mist |

| Cutting time | 2hr20min |

Work size:50 x 50 mm

Depth of cut:8 mm