Product

MUGEN COATING Series

This series adopted MUGEN COATING that continues evolving based on TiAlN (Titanium Aluminum Nitride) coating. As the coating characteristics, the hardness is Hv3,400 and the oxidation temperature 1,100deg.C that recommended for various materials from raw steels to hardened steels, and any coolant types such as water soluble, oil, air blow and oil mist. Although copper cutting is hard to get the coating effects in general, MUGEN COATING reduces tool wear.

Comparison of Rigidity

The comparison of rigidity for our MUGEN COATING and rival’s TiAlN coating.

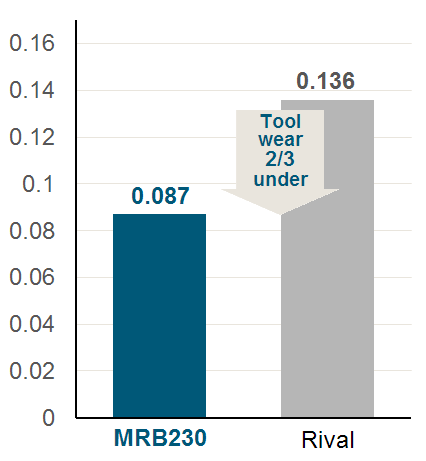

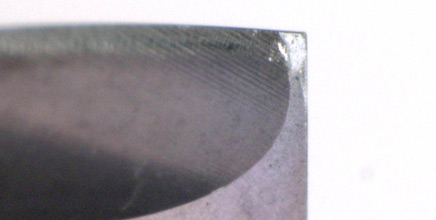

[Material] STAVAX 52HRC(SUS420J2)

MRB230 R1x10

Tool Wear0.087mm

Rival R1x10

Tool Wear0.136mm

n:10,000min-1 Vf:1,500mm/min ap:0.1mm×ae:0.2mm

Water soluble fluid Cutting time:132min Cutting length150m

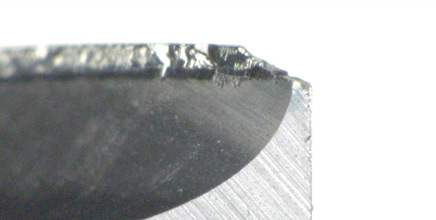

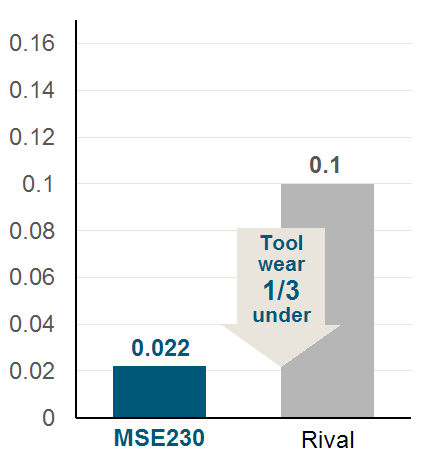

[Material] Carbon Steels S50C

MSE230 φ6

Tool Wear0.022mm

Rival φ6

Tool Wear0.1mm

n:3,400min-1 Vf:600mm/min ap:9mm×ae:1.2mm

Water soluble fluid Cutting time:33min Cutting length20m

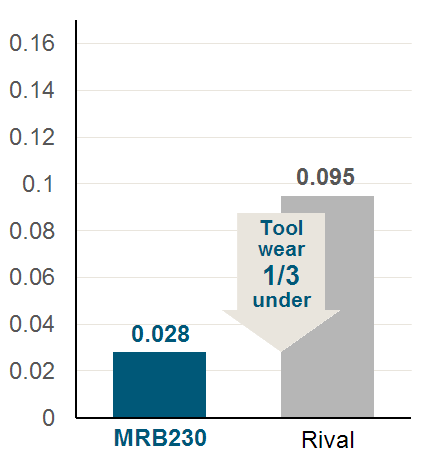

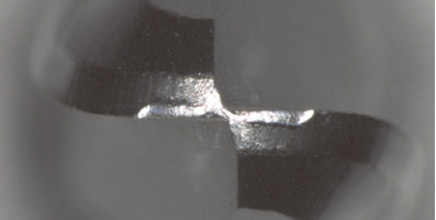

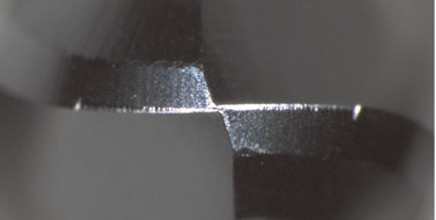

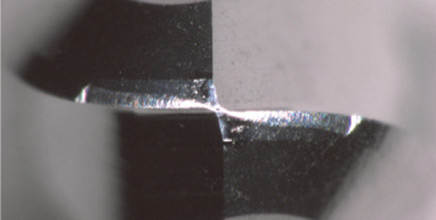

[Material] Copper

MRB230 R1x6

Tool Wear0.028mm

Rival R1x6

Tool Wear0.095mm

n:12,000min-1 Vf:1,200mm/min ap:0.2mm×ae:0.3mm

Water soluble fluid Cutting time:5hr44min Cutting length365m