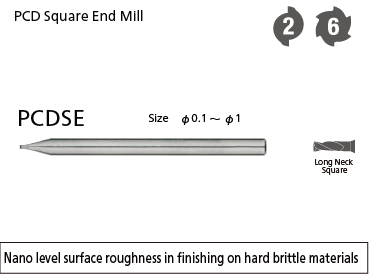

Product

PCD Core Line

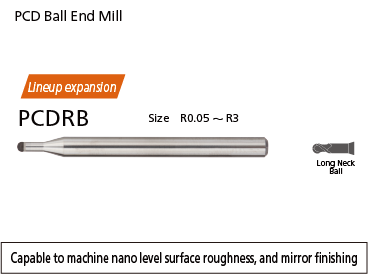

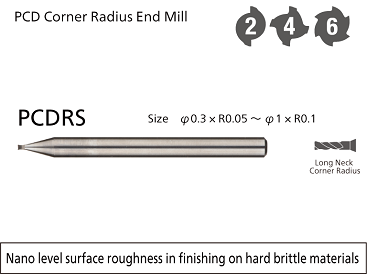

Product

PCD Core Line

Achieves nano-level surface roughess like a mirror surface by milling

Achieves nano-level surface roughess like a mirror surface by milling

What is PCD end mill?

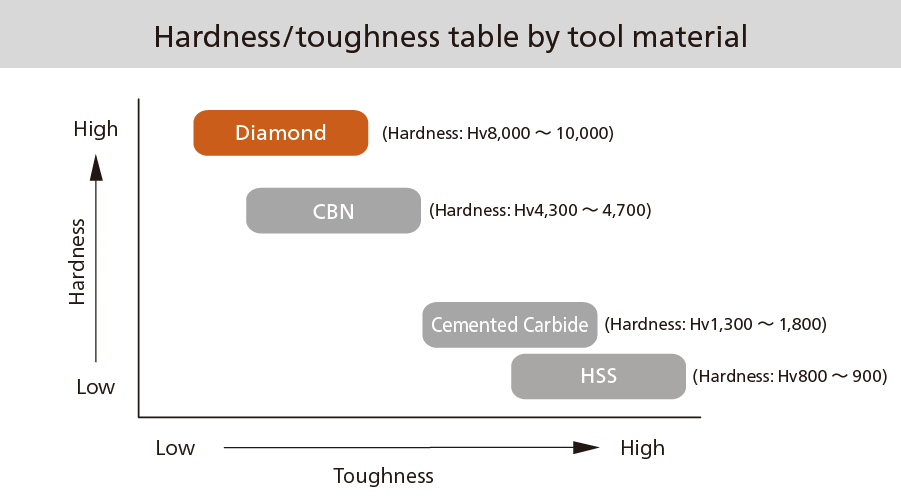

This is an end mill that uses PCD (polycrystalline diamond) as the tool material. Like monocrystalline diamond, it has high hardness and excellent wear resistance, but it is vulnerable to heat and has limited applications. With the aim of obtaining nano-level finishing grades, we have developed many technical elements such as special cutting edge shapes, production methods, and know-how for processing. We achieve a higher grade of finished surface quality by milling.

Leaflet

PCD Trial Kit

For first-time users of PCD end mills

PCD end mills achieve outstanding surface quality by taking advantage of their long tool life in the finishing process of high-hardened steel and cemented carbide, but it is also true that the machine tools used and the environmental conditions such as temperature and vibration are very severe. Therefore, we would like to introduce the "PCD Trial Kit" that can actually test the processing of high-hardened steel aiming for "polishing-free" using the PCD ball end mill "PCDRB". The measurement of processing results by our engineers is also included in the set, and we will back up according to the results of each customer.

Measurement details

We analyze and report on the tools and workpieces after machining from the following perspectives.

Tool observation

Work condition

Download NC data

Download the NC program for the PCD trial kit from the link below.

*To download, there should have a download code that comes with the trial kit.

Download