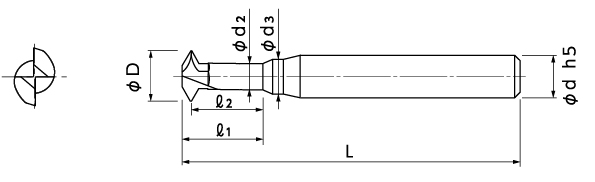

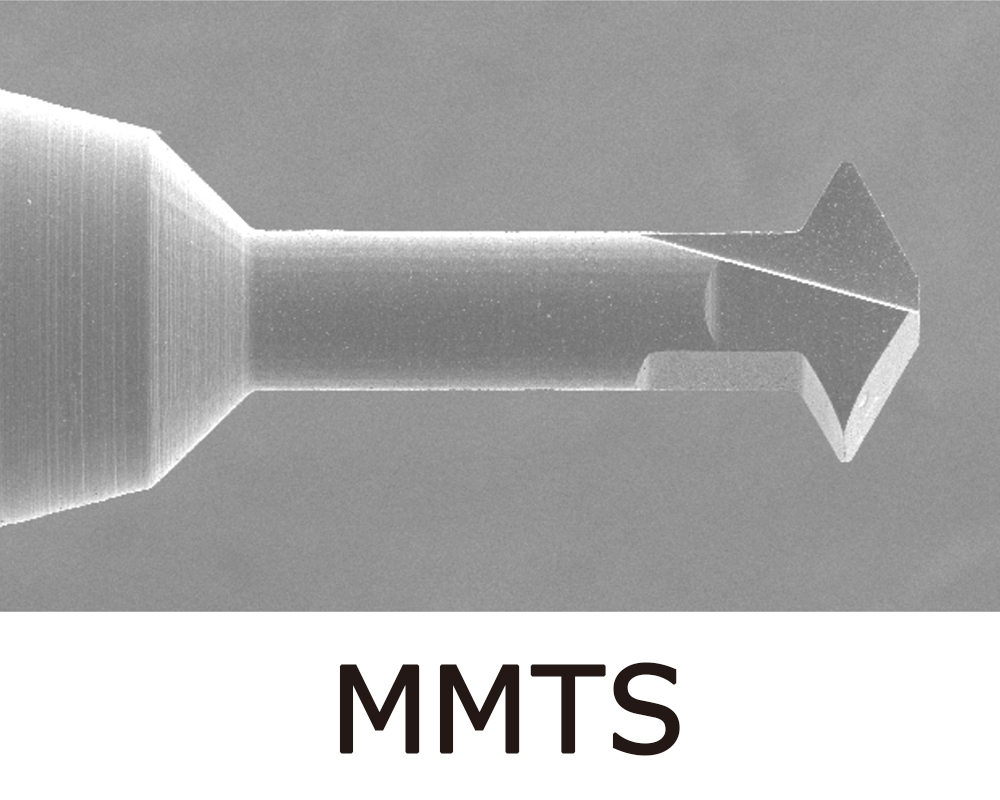

MMTS

MUGEN COATING Micro Thread Cutting Tool (for Internal Thread)

●World smallest threaded size 0.1mm is possible to cut.

●When the tool is broken during thread milling,the wreckages can be easily removed as the tool diameter is smaller than the pilot hole.

●MUGEN COATING realized long tool life.

Coating

MUGEN COATING

Material

Micro Grain Carbide

Cutting Possibility of Work Material Hardness

Up to 40HRC

Number of Flutes

2 Flutes

φd h5

Applications

Thread milling

Work Materials

Machinable indication by  ,

,

| Carbon Steel | Alloy Steel | Prehardened Steel | Hardened Steel | Stainless Steel | Heat Resistant Alloy | Aluminum Alloy | Copper | Resin | Graphite | Hard Brittle Material | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ~ 52HRC |

~ 60HRC |

~ 65HRC |

~ 70HRC |

||||||||||

| Carbon Steel | Heat Resistant Alloy |

|||

|---|---|---|---|---|

| Alloy Steel | Aluminum Alloy | |||

| Prehardened Steel |

Copper | |||

| Hardened Steel |

~ 52HRC |

Resin | ||

| ~ 60HRC |

Graphite | |||

| ~ 65HRC |

Hard Brittle Material |

|||

| ~ 70HRC |

Hard Brittle Material |

|||

| Stainless Steel | ||||