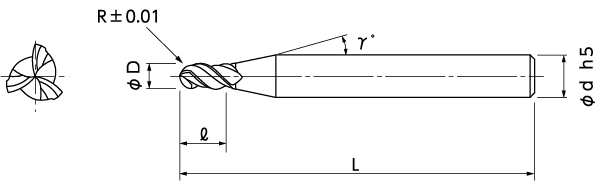

MSB345

MUGEN COATING 3-Flute Ball End Mill

●Original 3-flute design and unequal flute spacing to suppress chattering realize high efficient machining.

Coating

MUGEN COATING

Material

Micro Grain Carbide

Cutting Possibility of Work Material Hardness

Up to 52HRC

Number of Flutes

3 Flutes

Helix Angle

45°

φd h5

Applications

3D Milling

Work Materials

Machinable indication by  ,

,

| Carbon Steel | Alloy Steel | Prehardened Steel | Hardened Steel | Stainless Steel | Heat Resistant Alloy | Aluminum Alloy | Copper | Resin | Graphite | Hard Brittle Material | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ~ 52HRC |

~ 60HRC |

~ 65HRC |

~ 70HRC |

||||||||||

| Carbon Steel | Heat Resistant Alloy |

|||

|---|---|---|---|---|

| Alloy Steel | Aluminum Alloy | |||

| Prehardened Steel |

Copper | |||

| Hardened Steel |

~ 52HRC |

Resin | ||

| ~ 60HRC |

Graphite | |||

| ~ 65HRC |

Hard Brittle Material |

|||

| ~ 70HRC |

Hard Brittle Material |

|||

| Stainless Steel | ||||