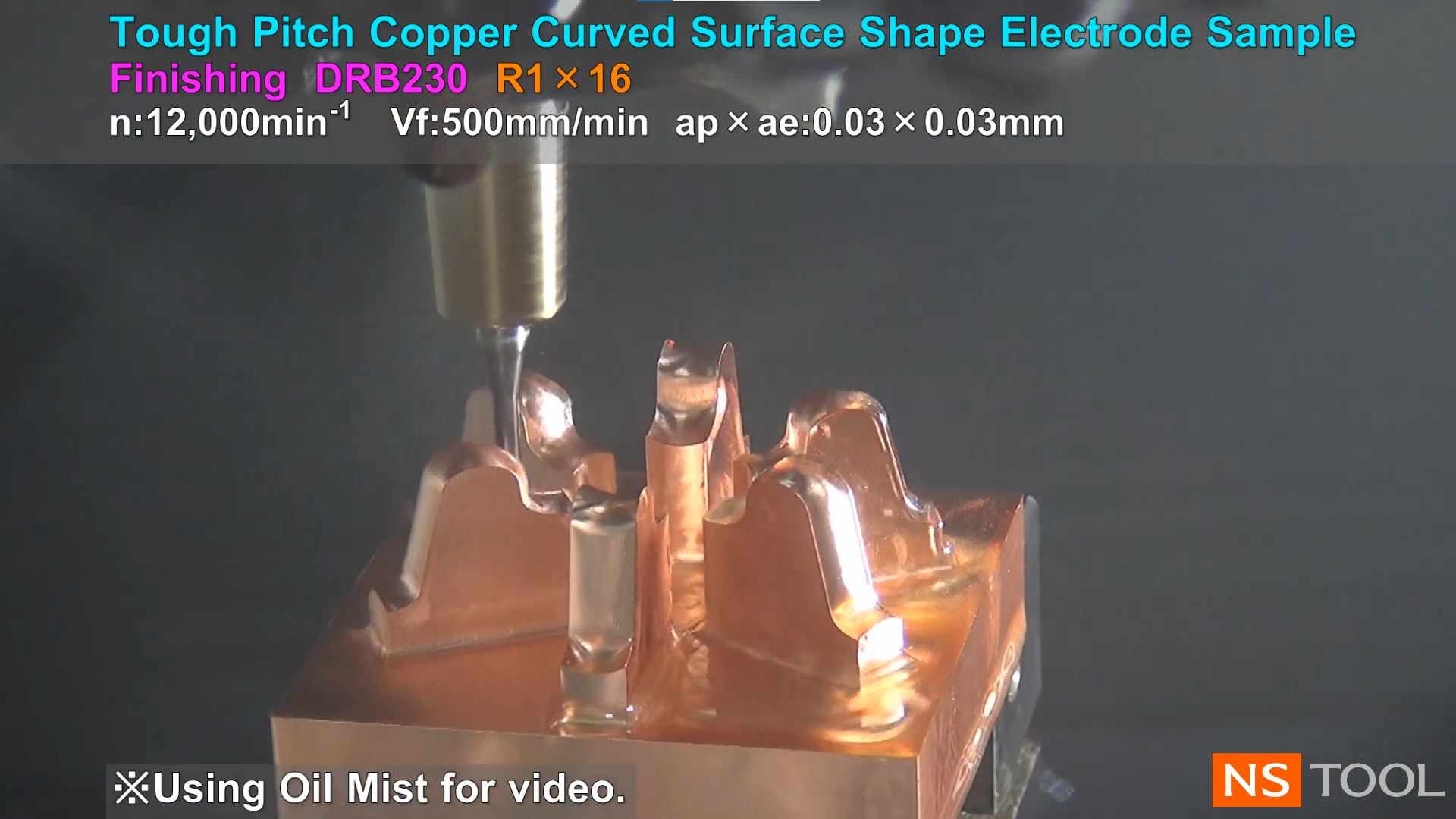

DRB230

Long Neck Ball End Mill for Copper Electrode

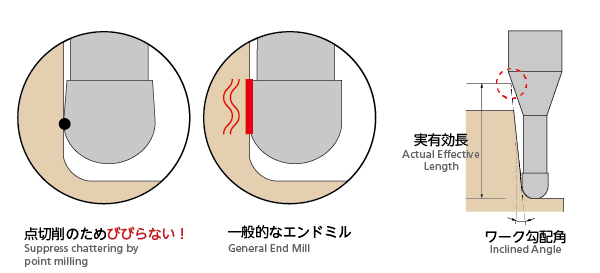

●Long neck ball end mill specialized for machining copper electrode.

●Sharp edge shearing ability and DLC coating realized high quality and stable a long life machining.

●Machining copper tungsten electrodes is also effective.

Coating

DLC COATING

Material

Micro Grain Carbide

Number of Flutes

2 Flutes

Helix Angle

30°

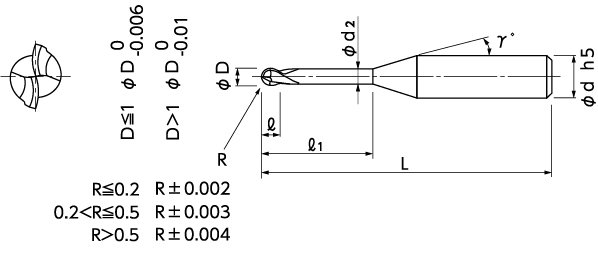

Conner

±0.002(R≦0.2) &

±0.003(0.2<R≦0.5) &

±0.004(R>0.5)

φd h5

Applications

3D Milling

Work Materials

Machinable indication by  ,

,

| Carbon Steel | Alloy Steel | Prehardened Steel | Hardened Steel | Stainless Steel | Heat Resistant Alloy | Aluminum Alloy | Copper | Copper Tungsten | Resin | Graphite | Hard Brittle Material | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ~ 52HRC |

~ 60HRC |

~ 65HRC |

~ 70HRC |

|||||||||||

| Carbon Steel | Heat Resistant Alloy |

|||

|---|---|---|---|---|

| Alloy Steel | Aluminum Alloy | |||

| Prehardened Steel |

Copper | |||

| Hardened Steel |

~ 52HRC |

Copper Tungsten | ||

| ~ 60HRC |

Resin | |||

| ~ 65HRC |

Graphite | |||

| ~ 70HRC |

Hard Brittle Material |

|||

| Stainless Steel | ||||