SFB200

CBN Super Finish Ball End Mill

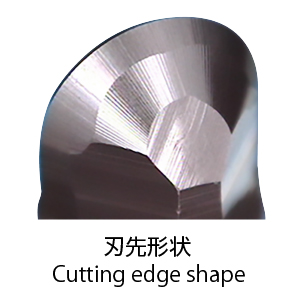

●Sharpened edge at R-center improves shearing ability.

●Continuous 10 hours machining on hardened steel of 60HRC.

●Long-lasting high surface accuracy Rz1.0μm.

●Save significant time at polishing process.

Material

CubicBoron Nitride

Cutting Possibility of Work Material Hardness

Up to 70HRC

Number of Flutes

2 Flutes

Helix Angle

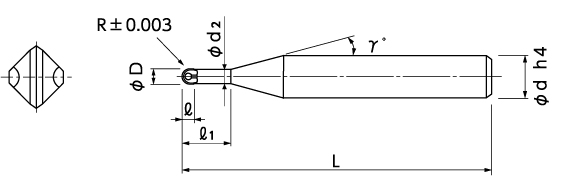

0°

Conner

±0.003

φd h4

Applications

3D Milling

Work Materials

Machinable indication by  ,

,

| Carbon Steel | Alloy Steel | Prehardened Steel | Hardened Steel | Stainless Steel | Heat Resistant Alloy | Aluminum Alloy | Copper | Resin | Graphite | Hard Brittle Material | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ~ 52HRC |

~ 60HRC |

~ 65HRC |

~ 70HRC |

||||||||||

| Carbon Steel | Heat Resistant Alloy |

|||

|---|---|---|---|---|

| Alloy Steel | Aluminum Alloy | |||

| Prehardened Steel |

Copper | |||

| Hardened Steel |

~ 52HRC |

Resin | ||

| ~ 60HRC |

Graphite | |||

| ~ 65HRC |

Hard Brittle Material |

|||

| ~ 70HRC |

Hard Brittle Material |

|||

| Stainless Steel | ||||