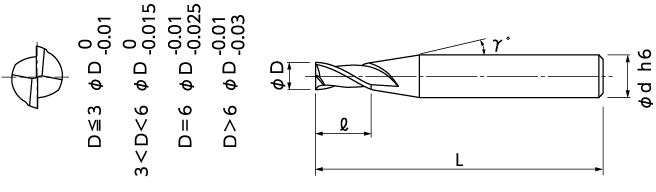

MX230

MUGEN COATING 2-Flute LEAD30 End Mill

●L/D=2 and helix 30° standard type applicable for both slotting and side milling.

Coating

MUGEN COATING

Material

Micro Grain Carbide

Cutting Possibility of Work Material Hardness

Up to 52HRC

Number of Flutes

2 Flutes

Helix Angle

30°

Applications

Side Milling

Applications

Slot Milling

Applications

Face Milling

Work Materials

Machinable indication by  ,

,

| Carbon Steel | Alloy Steel | Prehardened Steel | Hardened Steel | Stainless Steel | Heat Resistant Alloy | Aluminum Alloy | Copper | Resin | Graphite | Hard Brittle Material | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ~ 52HRC |

~ 60HRC |

~ 65HRC |

~ 70HRC |

||||||||||

| Carbon Steel | Heat Resistant Alloy |

|||

|---|---|---|---|---|

| Alloy Steel | Aluminum Alloy | |||

| Prehardened Steel |

Copper | |||

| Hardened Steel |

~ 52HRC |

Resin | ||

| ~ 60HRC |

Graphite | |||

| ~ 65HRC |

Hard Brittle Material |

|||

| ~ 70HRC |

Hard Brittle Material |

|||

| Stainless Steel | ||||