Product

Feature of NS TOOL Original Coatings

MUGEN COATING PREMIUM Plus

MUGEN COATING PREMIUM Plus

Hardness of Work Material

New developed coating realized cutting hardened steels from 45HRC to 70 HRC with high oxidation resistance and abrasion resistance

| NEW | |||

| MUGEN COATING | MUGEN COATING PREMIUM |

MUGEN COATING PREMIUM Plus |

|

| Hardness of Material | 50HRC | 60HRC | 70HRC |

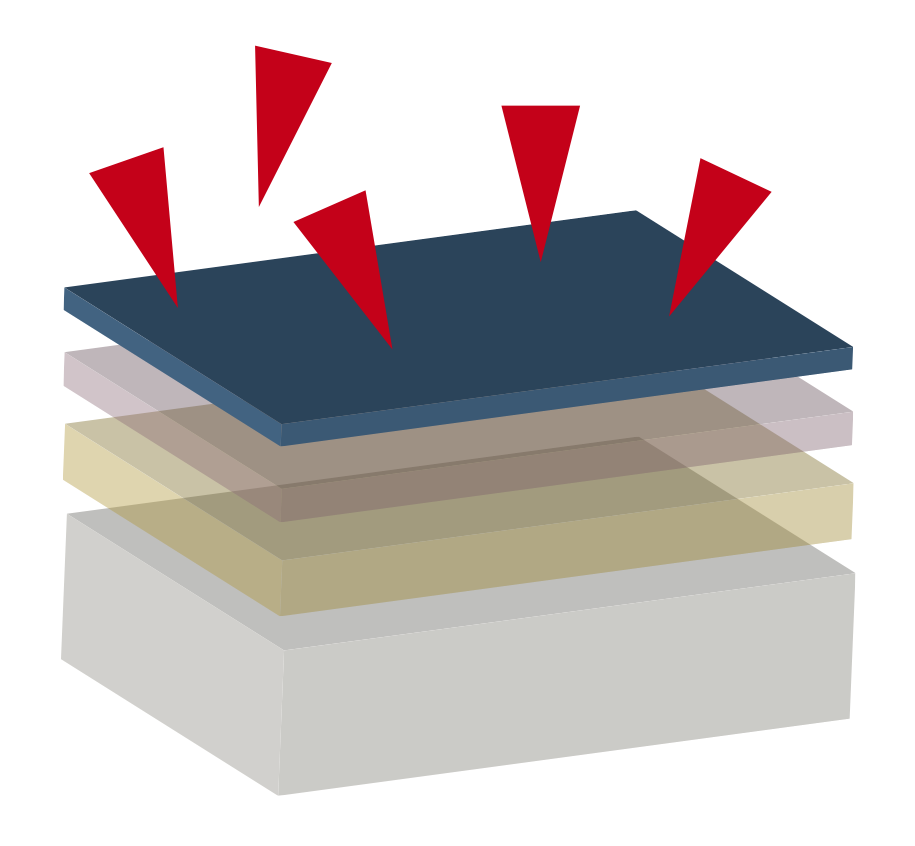

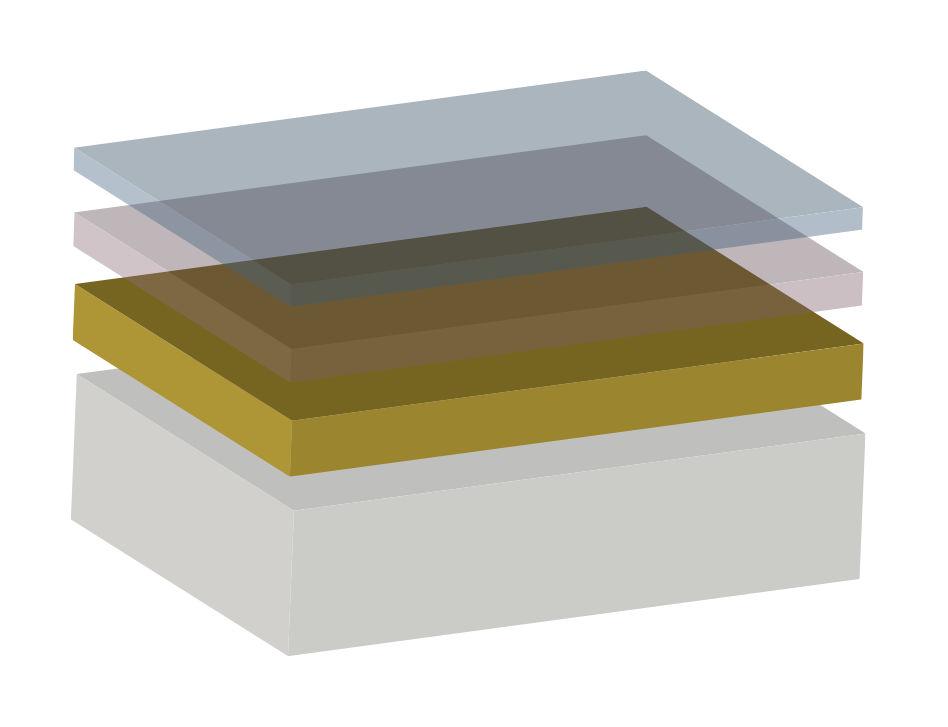

Role of coating

Oxidation resistant layer

Prevents oxidation due to heat generated during cutting

Hard coating layer

(Ultra micro crystal strucuture)

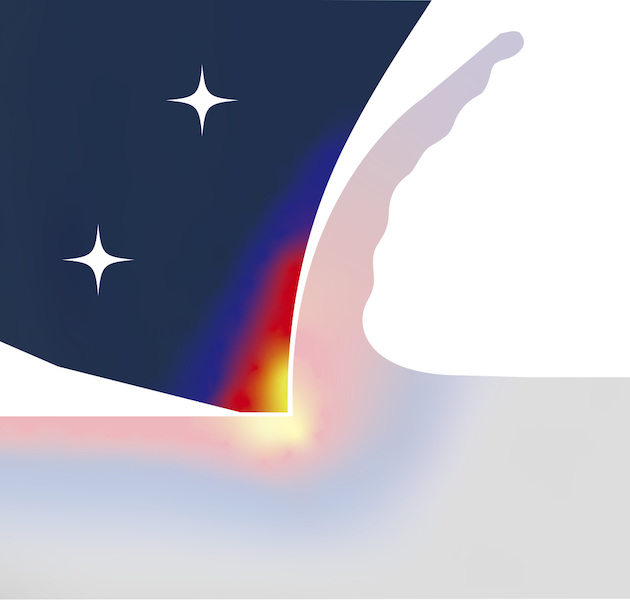

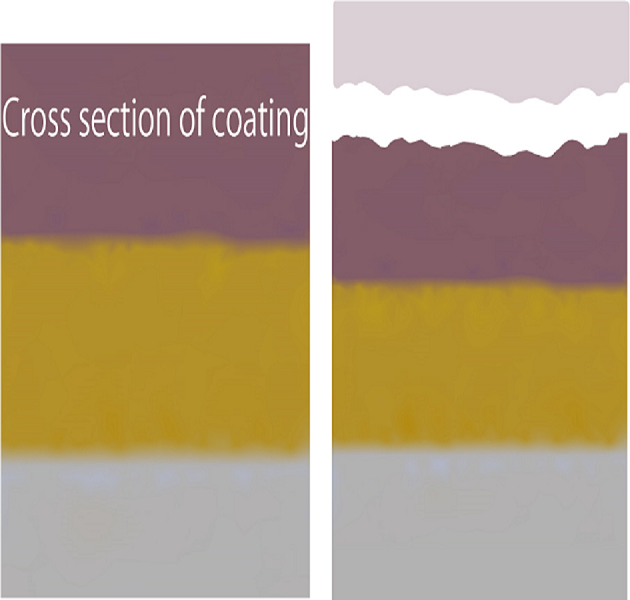

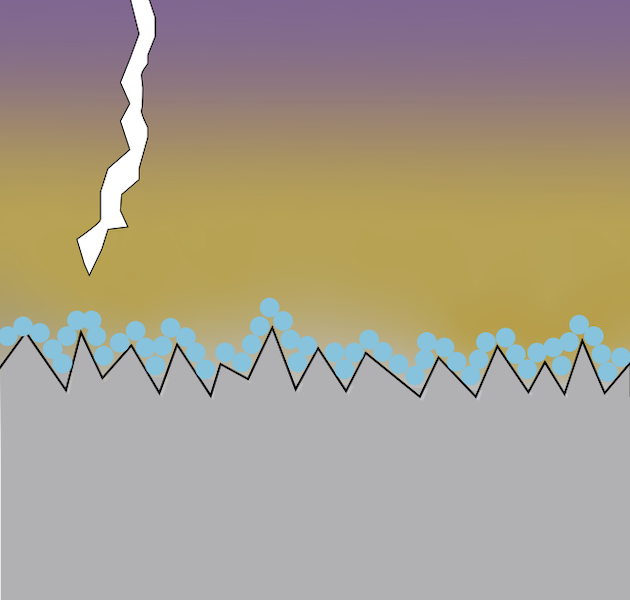

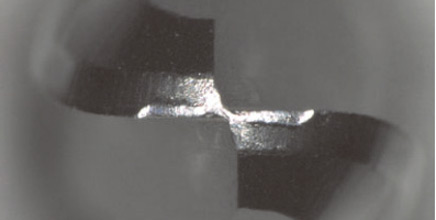

Image of wear progress cross section of coating

Tool wear can be reduced when machining on high hardened steel

High adhension

coating layer

(micro crystal structure)

Image diagram of crack growth and adhesion

Structure that is difficult to crack and propagate when impact forced

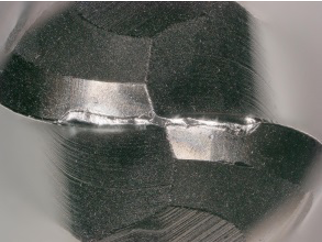

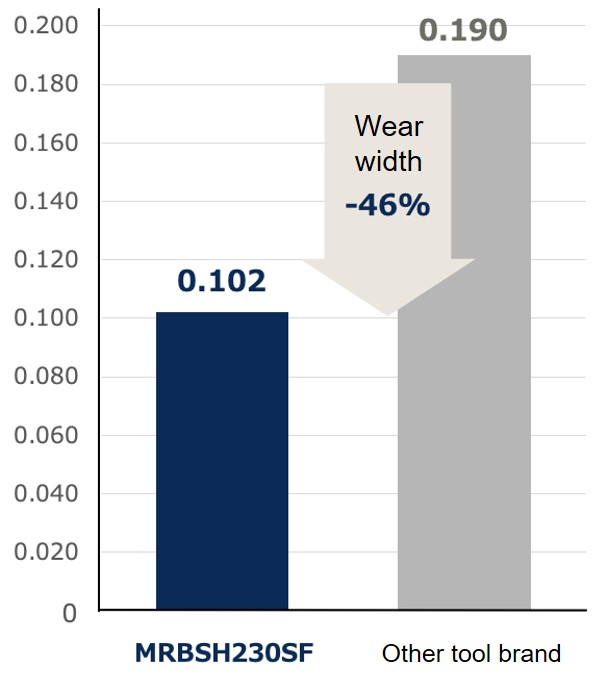

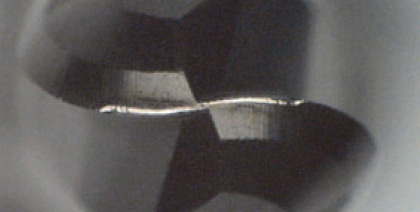

[Material] HAP40:60HRC(Powder HSS)

MRBSH230SF R1x6

Wear width 0.102mm

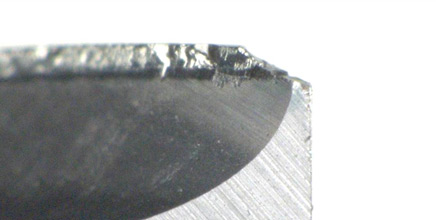

Other tool brand

Wear Width 0.190mm

n:20,000min-1 Vf:1,600mm/min ap:0.15mm×ae:0.3mm

Oil Mist Cutting time :70min

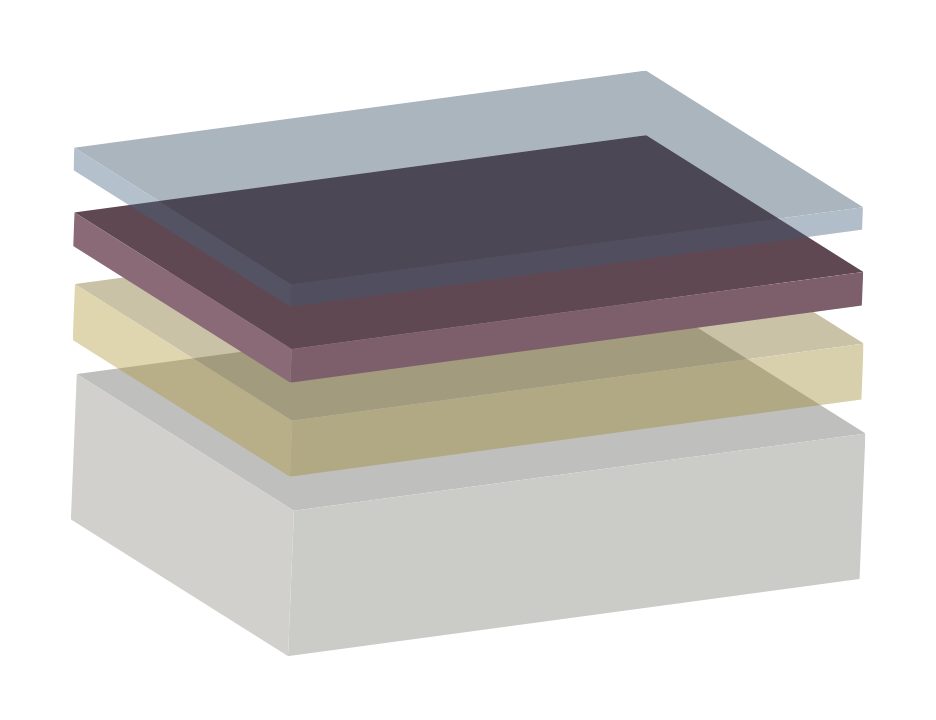

MUGEN COATING PREMIUM Series

MUGEN COATING PREMIUM Series

MUGEN COATING PREMIUM is specialized for hardened steels.Improved from MUGEN COATING and succeeded in keeping characteristics that enough to process high hard materials.

High oxidation temperature brings high heat resistance, MUGEN COATING PREMIUM known as also applicable for high heat-resistant steels recently.

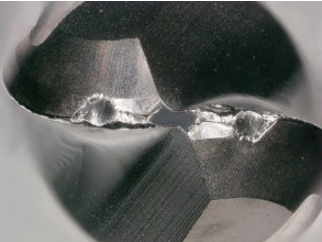

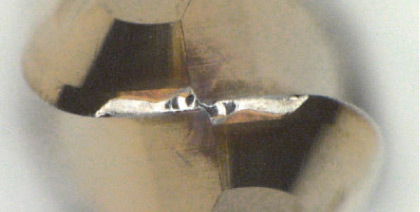

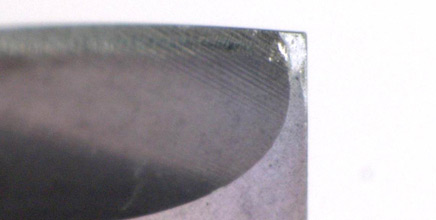

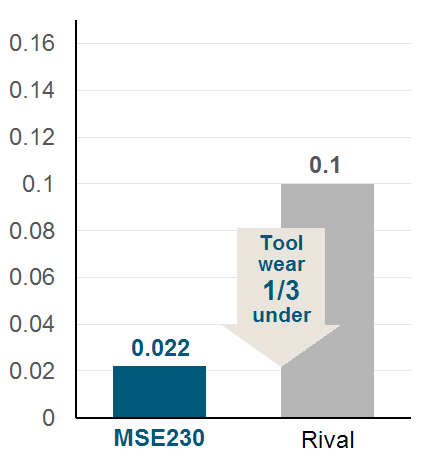

[Material] HAP40:60HRC(Powder HSS)

MRBH230 R1x6

Tool wear 0.029mm

Rival R1x6

Tool wear 0.1mm

n:20,000min-1 Vf:1,600mm/min ap:0.15mm×ae:0.3mm

Oil mist Cutting time: 18min Cutting length 25m

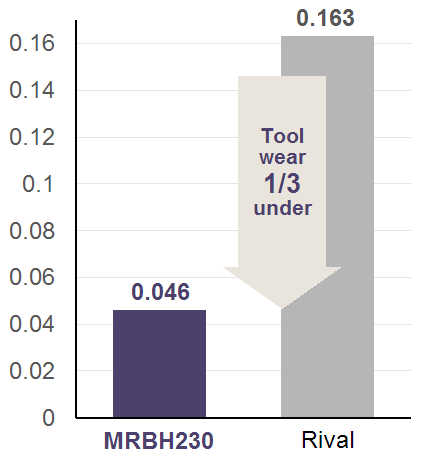

[Material] PD613 60HRC(SKD11)

MRBH230 R1x6

Tool Wear 0.046mm

Rivals R1x6

Tool Wear 0.163mm

n:25,000min-1 Vf:2,000mm/min ap:0.2mm×ae:0.3mm

Oil mist Cutting time:62min Cutting length100m

MUGEN COATING Series

MUGEN COATING Series

Even TiAlN based coating, MUGEN COATING has excellent characteristics to bring high rigidity and lubricity for machining hardened steels (60HRC), prehardened steels, soft irons and coppers as following cases. Also suits to any coolant such as water soluble, oil, air blow and oil mist, MUGEN COTING can be called mighty coating that applicable to any materials and coolants.

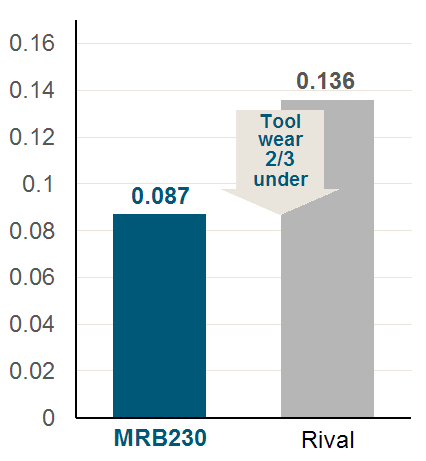

[Material] STAVAX 52HRC(SUS420J2)

MRB230 R1x10

Tool Wear 0.087mm

Rival R1x10

Tool Wear 0.136mm

n:10,000min-1 Vf:1,500mm/min ap:0.1mm×ae:0.2mm

Water soluble fluid Cutting time:132min Cutting length 150m

[Material] S50C

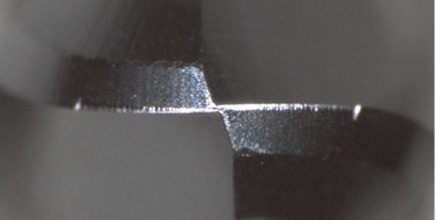

MSE230 Φ6

Tool Wear 0.022mm

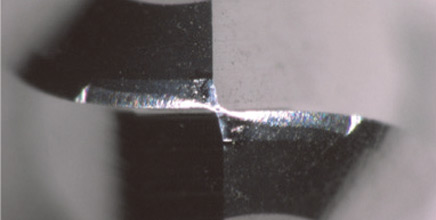

Rival Φ6

Tool Wear 0.1mm

n:3,400min-1 Vf:600mm/min ap:9.0mm×ae:1.2mm

Water soluble fluid Cutting time: 33min Cutting length 20m

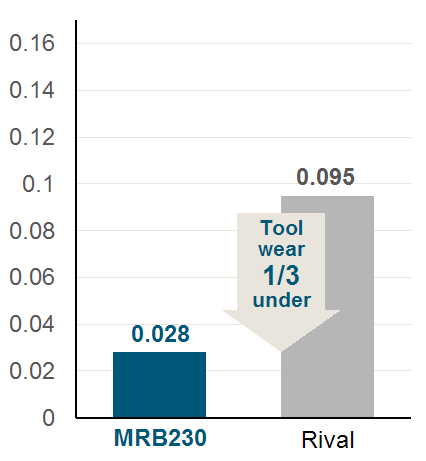

[Material] Copper

MRB230 R1x6

Tool Wear 0.028mm

Rival R1x6

Tool Wear 0.095mm

n:12,000min-1 Vf:1,200mm/min ap:0.2mm×ae:0.3mm

Water soluble fluid Cutting time: 5hr44min Cutting length: 365m

DLC-COATING

DLC-COATING

DLC (Diamond-Like Carbon) COATING is composed from film like characteristic of carbon and made up of amorphous structure of diamond and graphite. Hardness is Hv 4,000 and friction coefficient is 0.1 μm. Coated surface is very smooth which achieves Ra 0.02 μm and very low welding that realizes excellent surface in cutting of aluminum. X-COATING is suitable for cutting nonferrous metals, especially for aluminums, but not for ferrous metals.

DIAMOND COATING

DIAMOND COATING

High stability is achieved by excellent wear resistance and high adhesion technology made of high-purity diamond that does not contain binders and impurities.

MUGEN MICRO COATING

MUGEN MICRO COATING

This is a TiAIN (titanium aluminide) -based coating developed as a special coating for ultra-small diameter sizes with an outer diameter of 0.1 mm or less, which NS TOOL specializes in.

X-COATING (Stop production 2020.08)

X-COATING (Stop production 2020.08)

X-COATING is TiCN based coating with characteristics of high hardness Hv 3,000 and excellent adhesion, but weak in milling heat from high speed machining more than cutting speed 100 m/min. Accordingly, X-COATING achieves versatility in wet-cutting and general cutting condition with cutting speed less than 100 m/min.

Application List of Coatings

| Coating | |||||||

|---|---|---|---|---|---|---|---|

| MUGEN COATING PREMIUM Plus | MUGEN COATING PREMIUM | MUGEN COATING | DLC | Diamond coating for Hard Brittle Material | Diamond coating for graphite | ||

| Work material |

66~70 HRC | ||||||

| 56~65 HRC | 45~55 HRC | ||||||

| Prehardened steels | |||||||

| Raw material | |||||||

| Copper | |||||||

| Aluminum | |||||||

| Cemented Carbide・ Ceramics・ Glass | Graphite・High Silicone Aluminum alloy・Fiber Reinforced Plastics | ||||||