Technology

High Efficient Milling on Titanium Alloy Ti-6Al-4V MSXH440R / Power Radius End Mill

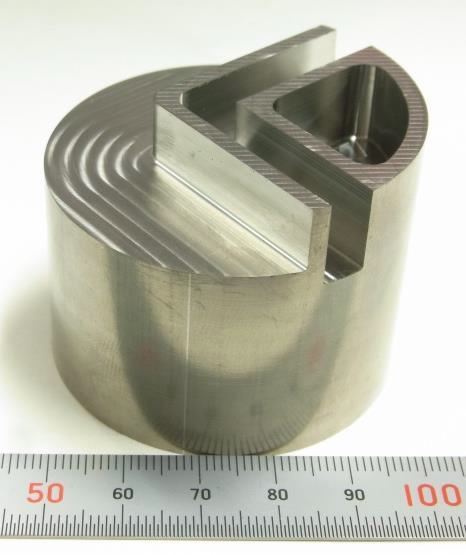

Work size: φ50×40(mm)

Material: Ti-6Al-4V

Cutting time: 3 min 9 sec

High efficient machining sample of tough material, titanium alloy.

Tool

MSXH440R

Φ6×0.5

•Improved designs of unequal helix angle and flute spacing to suppress from chattering to realize stable milling progression.

•Original spiral design at corner radius flutes improves cutting edge performance!

•Designed for high rigidity to suppress corner radius flute breakage even on rough milling stresses.

•Adopted Mugen Coating Premium to suppress from chattering to realize stable milling progression, improved heat resistance and cutting edge strength to protect from milling heat influence.

Cutting Condition

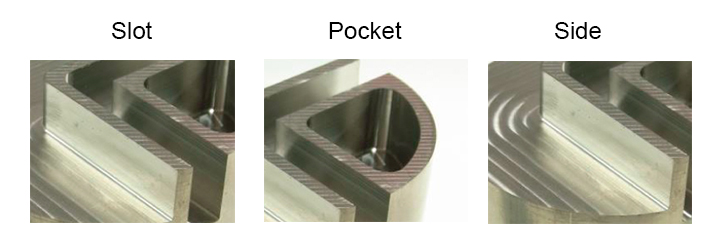

| Cutting part | Slot | Side | ||||

| Cutting process | Roughing | Finishing | Roughing | Finishing | Roughing | Finishing |

| Tool | MSXH440R φ6×R0.5 | |||||

| Spindle speed (min-1) |

3,600 | 3,600 | 3,600 | |||

| Feed (mm/min) |

400 | 400 | 1000 | 400 | ||

| Depth of cut ap×ae(mm) |

ap6 | 12×0.1 | 6×3 | 12×0.1 | 9×1.2 | 9×0.1 |

| Coolant | Water-soluble fluid | |||||

| Cutting time | 25 sec | 25 sec | 51 sec | 9 sec | 65 sec | 14 sec |

Comment

Completed with just 1 tool, in 3 minutes!

Realized high efficient milling by effect of MUGEN-COATING PREMIUM’s high heat-resistance and unique edge design.